How To Apply A Contactor To A Lighting Application

Question:

How do I apply a contactor to a lighting load?

Answer:

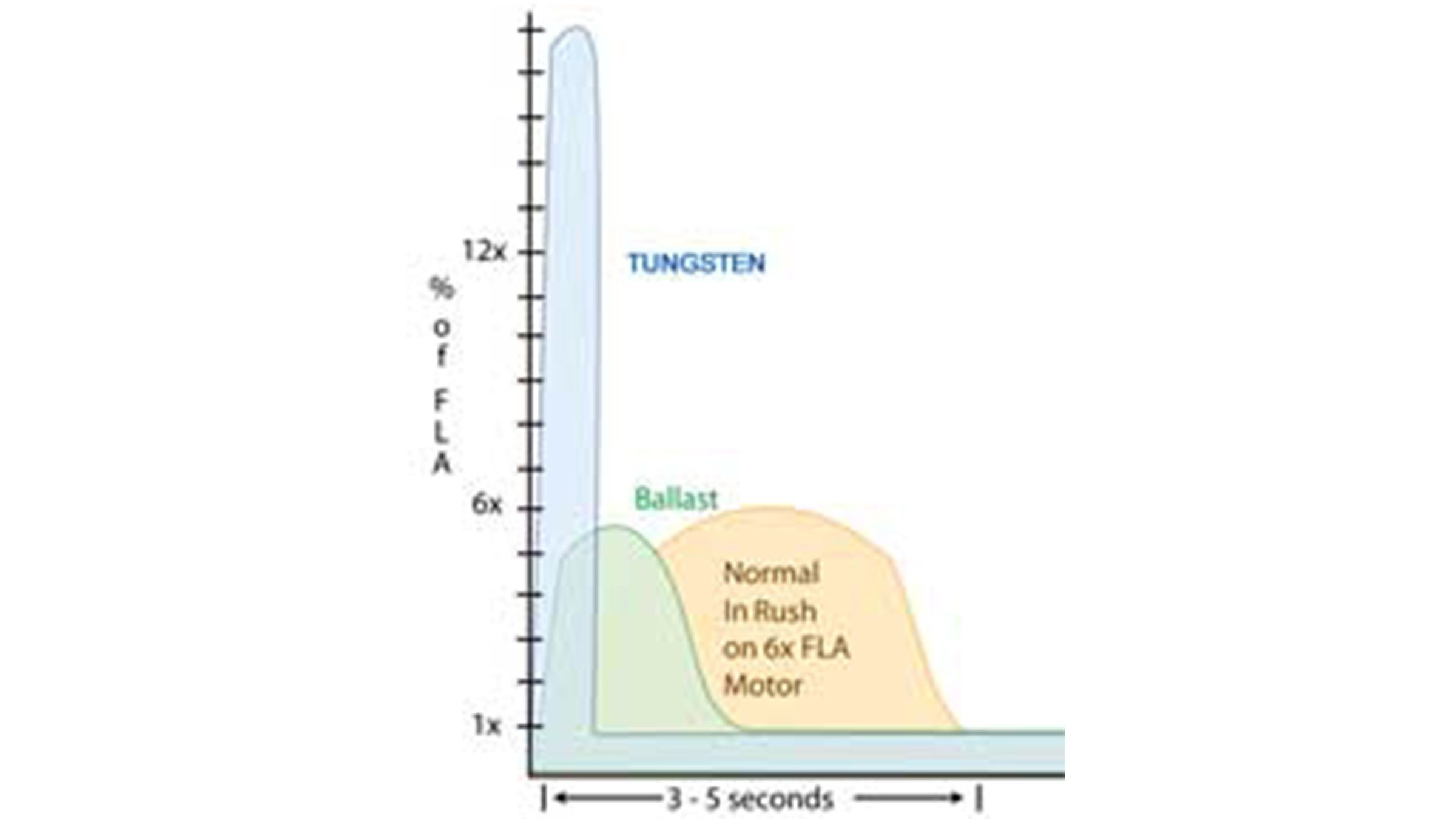

Lighting applications present high inrush in a very short time frame, making it difficult to properly apply contactors.

The tungsten filaments of incandescent lamps have a very low ohmic resistance when cold. A looped tungsten wire simply represents a short-circuit until the wire begins to heat-up and illuminate in a vacuum. This short-circuit style inrush is on the order of 17 times the continuous ampere draw but only lasts a few milliseconds. This means that tungsten (incandescent) lighting applications are one of the most difficult types of loads you might connect to a contactor and may not be considered a resistive load.

Now consider lighting that uses a ballast. This includes fluorescent, mercury vapor, HID, low pressure sodium and a host of other types of lighting that uses a ballast. A ballast is a specific type of inductor and all inductors have an inrush current similar to induction motors, and therefore are reactive loads rather than resistive.

It is common practice in Europe to use manufacturer’s technical data to apply contactors to either incandescent or ballast lighting loads. Rarely do European engineers or electricians discuss “lighting loads” as if tungsten and ballast loads are treated equally because tungsten is a much more difficult application.

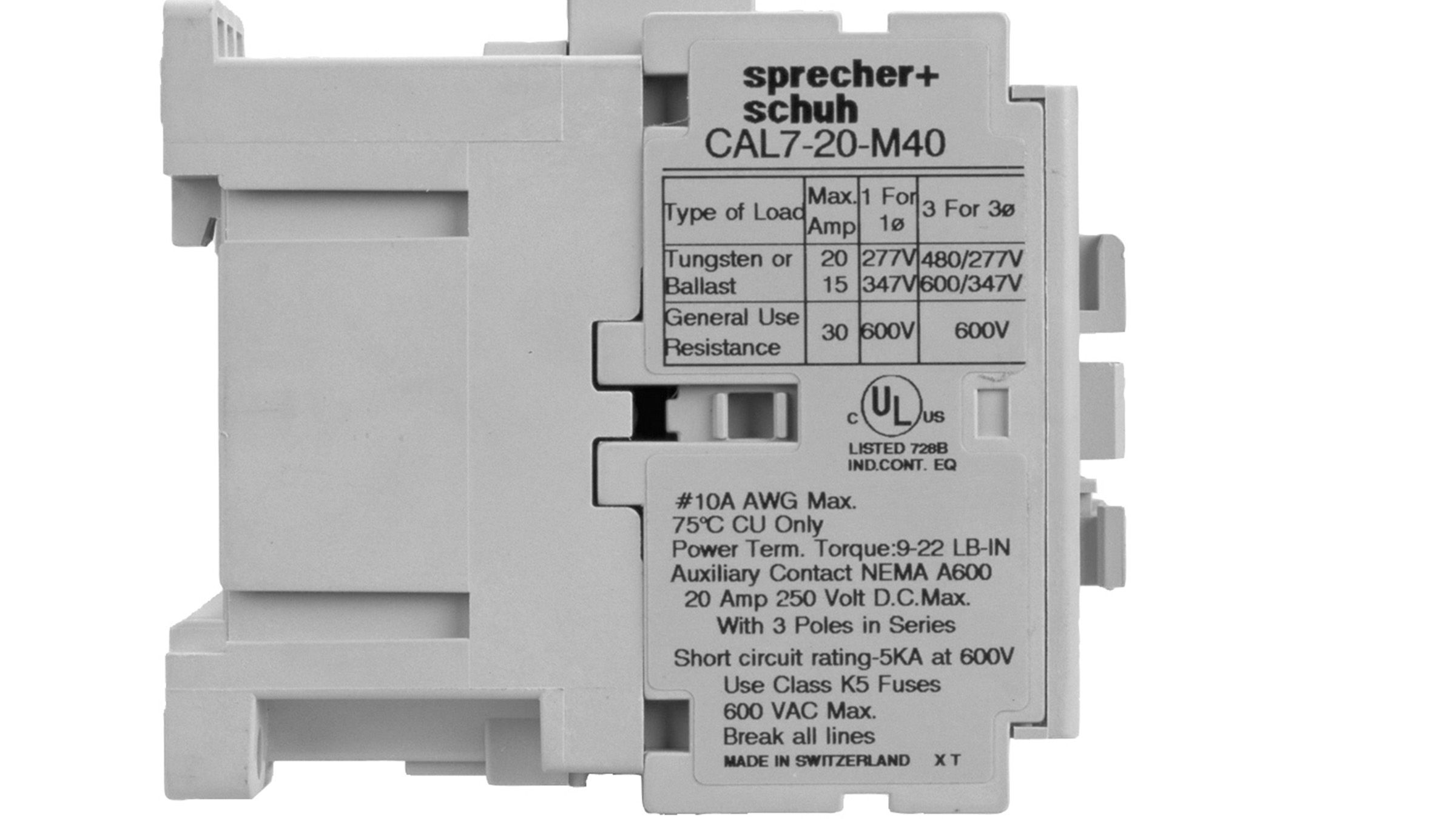

In contrast, it is common practice in North America to combine tungsten and ballast applications into one group. UL and CSA provide for combining lighting applications, resulting in a lighting contactor rating, and a different label is required compared to a HP/KW rated contactor label, even though the contactors may be identical.

CAL7 electrically held and CALV7 mechanically held contactors are cUL rated and labeled for tungsten and ballast lighting applications. CALV7 mechanically-held is different from a mechanically interlocked contactor, and are often utilized for parking lots or sport fields. A CV7-* mechanical interlock can be added to any CA7 contactor which includes coil clearing contacts as the coil of a CV7 is only momentarily rated.

Engineering practice permits 2.5 x Ie to be applied to a contactor when 3 poles are connected in parallel for single phase discharge lamp (ballast lighting) applications - for example, a CAL7-20-M40-* Lighting Contactor plus a CA7-P-B23 Parallel Link. Paralleling Links can be used on a 50A ballast load. Applying parallel conductors to incandescent lamp loads does NOT result in a greater permissible load. This trick of the trade might be used in single phase tanning beds.

For additional information please contact your nearest authorized distributor, sales representative, or call our customer service or technical support lines.

Related Links