PCS Series B Or PCEC Makes No Attempt To Start Attached Motor

Question:

The LED comes on continually or faults out but there is no output.

Answer:

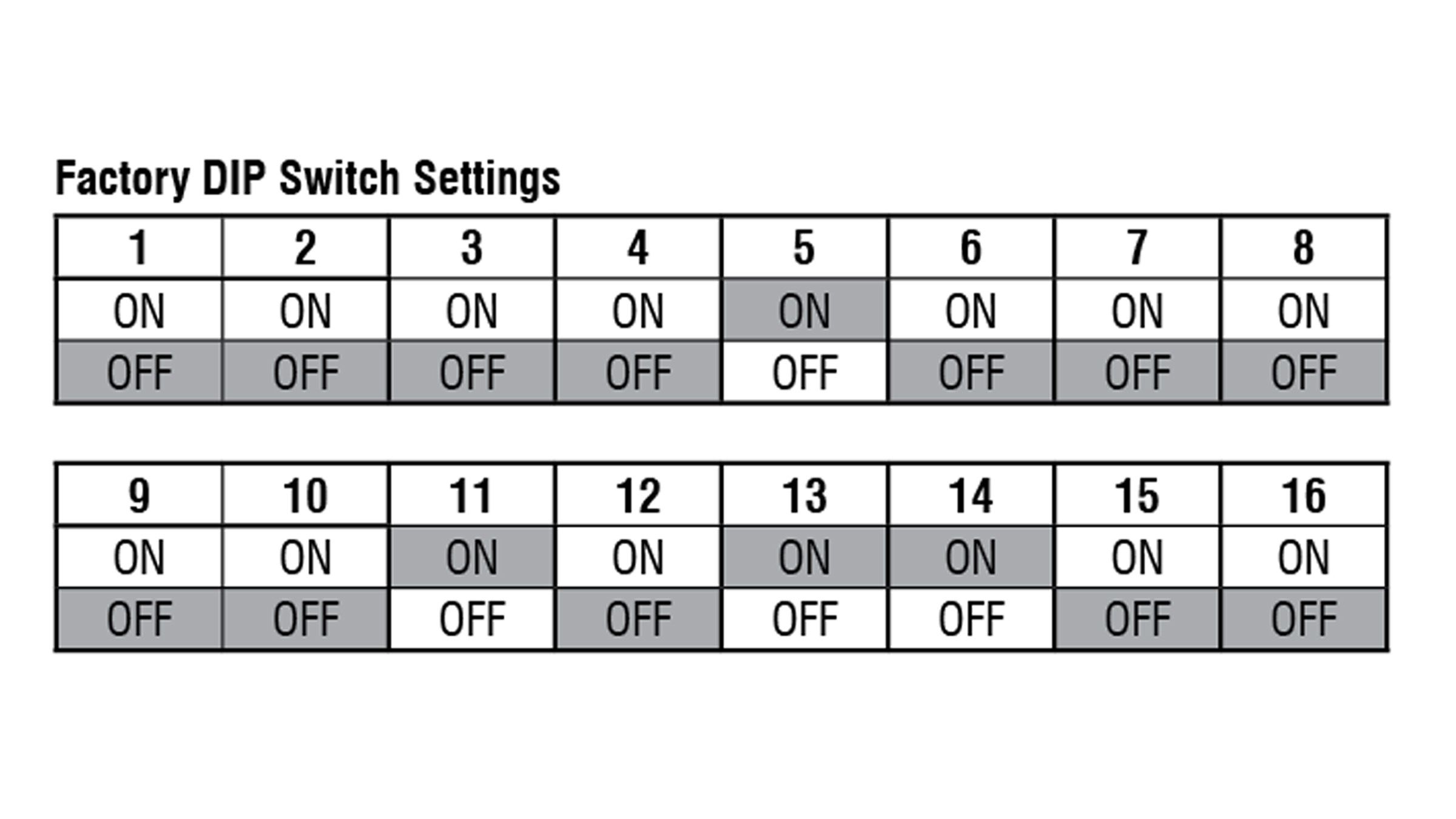

Check the setting of LINE / DELTA dip switch 15.

For PCS Softstarters

- If you have a line connected motor where the 3 leads from the motor go to T1,T2 & T3 on the PCS load side, Dip switch #15 should be set to ON (switch up).

- If you have a delta connected motor where the 6 leads from the motor go to T1,T2 & T3 PCS load side and T6, T4 & T5 on the PCS line side, Dip switch #15 should be set to OFF (switch down).

- See PCS instruction sheet for proper motor wire connections.

For PCEC Hydraulic Elevator Softstarters

- If you have a line connected motor where the 3 leads from the motor go to T6,T4 & T5 on the FC Contactors (PCE load side wired to the top side of the FC Contactor), Dip switch #15 should be set to ON (switch up). If dip switch #15 is set to Delta Connected (down) and the motor is a 3 wire Line Connected, the unit will attempt to turn on, but will not turn a motor.

- If you have a delta connected motor where the 6 leads from the motor go to T1,T2 & T3 load side of PCE and T6, T4 & T5 on the Fault Contactor (FC), Dip switch #15 should be set to OFF (switch down). If dip switch is set to Line Connected (up), but motor is a 6-wire Delta Connected, unit will fault on an Open Load indicated by 4 flashes.

- See PCEC manual for proper motor wire connections and additional details if Dip switch #15 is not set correctly.

For additional information please contact your nearest authorized distributor, sales representative, or call our customer service or technical support lines.