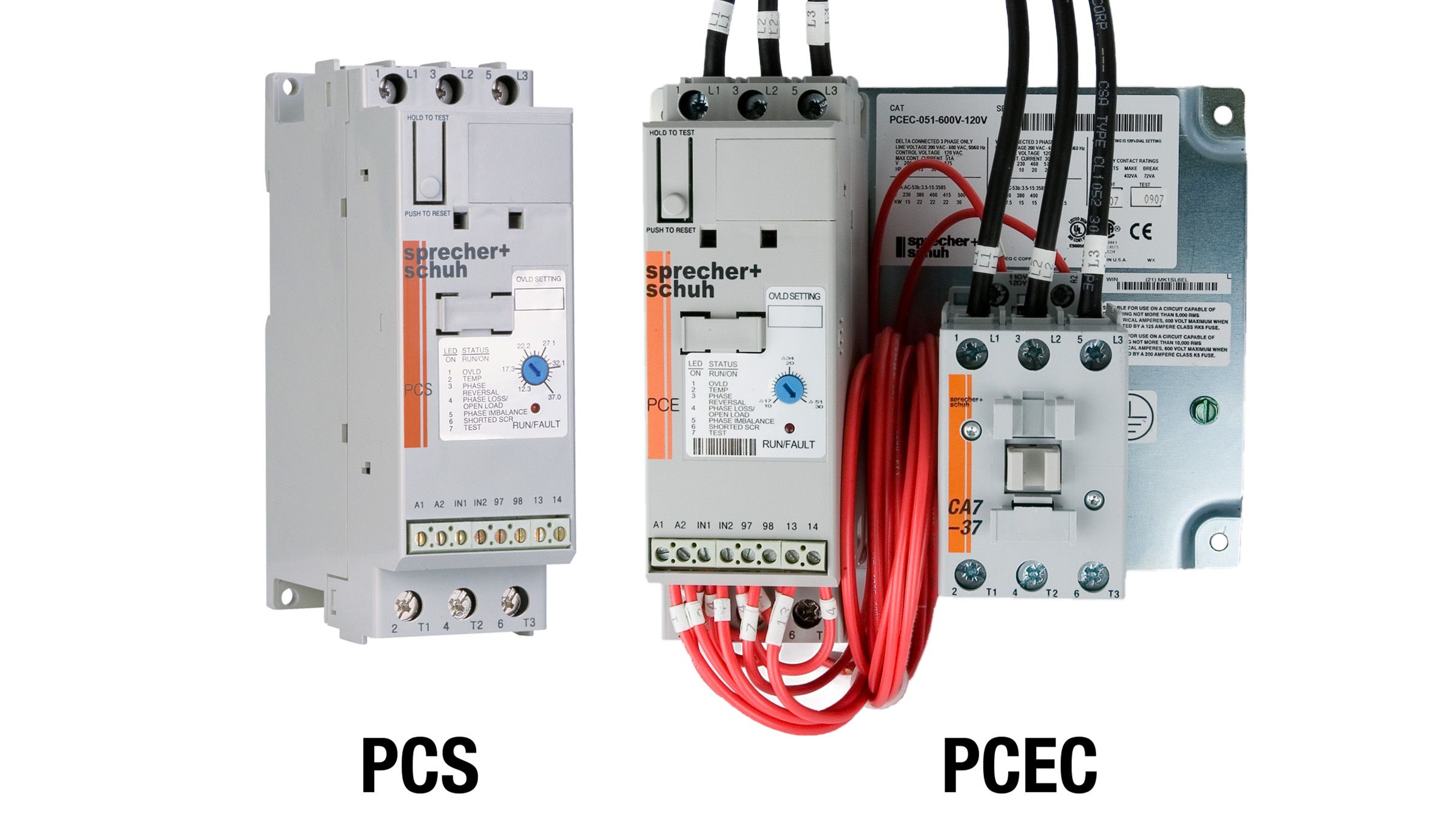

PCS Versus PCE Softstarters For Elevator Applications

Question:

What is the difference between a PCS and PCE softstarters? Will PCS work in an elevator application?

Answer:

The PCS and PCE (or PCEC) softstarters look similar, but have one major difference in the function of the 97/98 terminals.

Often customers look at Sprecher + Schuh products to replace an existing competitor product. The technical specifications of PCS softstarters may match many features of older softstarters or competitor elevator starters. However, for wye-delta applications the PCE softstarter is the best choice. On the surface it may appear that PCS and PCE softstarters are the same device but there are important differences. One major difference is that PCE uses an external fault contactor and this is quite different from an external by-pass contactor. Hydraulic elevator codes require an external fault contactor in line with the soft starter. A fault contactor ensures all three motor winding legs are opened during a fault condition to shut down the motor.

Control power is applied to the PCE terminals A1-A2 constantly. When the start enable signal is sent to terminals 1N1 and 1N2 the soft starter will ramp up the motor to full voltage and the LED run light will remain ON. When control power is first applied to A1-A2 of the PCE the terminals 97-98 close and in turn closes the fault contactor which remains closed until there is a fault encountered. When a fault occurs, the contact between 97-98 opens and the fault contactor opens. The PCE reports the fault by blinking the LED. Please note that the fault contactor is supplied with the PCEC model and PCE is the controller by itself. See the PCEC product page for more information.

PCE Features Not On PCS

- No Kick Start Capability

- Not needed in Elevator applications

- Normally Open Fault contact held Closed

- Fail Safe Condition

- Selectable Phase Relationship

- ABC or CBA phase rotation

- Ability to disable Phase Imbalance

- Motor overload would still protect motor, since one leg current may go high.

- Programmable Stop Delay

- Different Overload Label

- Has both Delta and Line FLA scales

The PCS soft starter functions the opposite with respect to the contact between 97-98. On a PCS the contact between 97-98 is normally open and does not close until there is a fault encountered. This means you cannot connect an elevator fault contactor to 97-98. Auxiliary contact marked 13-14 is a normally open contact which should be used to indicate up-to-speed. Alternatively, it can be switched to normal for immediate change of state upon receiving the start command. Even if you add an optional (external) side mount auxiliary, either normally open or normally closed, they are designed to change state with the starter and none of these auxiliaries can be used to hold-in (maintain) a fault contactor. Please reference the PCS product page for more information.

The simple fact is if a PCS softstarter for used in a hydraulic elevator wye-delta application then it won’t work as required. The customer will be calling for Tech Support and we will tell them to return the PCS softstarter to the seller and get a PCE elevator softstarter.

For additional information please contact your nearest authorized distributor, sales representative, or call our customer service or technical support lines.